HMI Programming is one of the areas we specialise in here at IRS Consultants. Human machine interface (HMI) software is used to bridge the gap between operators and systems. This is in order to control operations. Some software versions help to translate data. This is from industrial control systems into visuals that humans can read.

A great choice

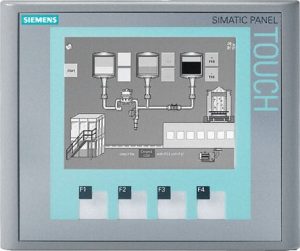

There are several aids and tools that are under the control of human operators. For example, a physical aspect of HMI might be a machine with push buttons or a touch display. It also has the primary focus of problem solving in a more naturalistic setting at the same time.

There are several aids and tools that are under the control of human operators. For example, a physical aspect of HMI might be a machine with push buttons or a touch display. It also has the primary focus of problem solving in a more naturalistic setting at the same time.

If you look from an industrial view, HMI helps users to understand and monitor production. It will respond to changes in demands. Consequently, this results in an increase in output and better efficiency.

Something to keep in mind is that HMIs tend to be most common on machines that are Windows-based. They communicate with programmable logic controllers as well as other industrial controllers.

SCADA software is the perfect pairing for HMI software. The reason for this is that the automation of a space safety and of connected machinery go hand in hand. Machines tend to work at high speeds. This makes it hard for people to intervene and compute the actual throughput of the system. Therefore, software like SCADA needs integrating to allow for smooth function.

Highly beneficial

You can integrate HMI software into many technologies. This allows for more efficient and error free work. Combining these can help forecast system defects and predict behaviour. This helps plan for breakdowns so that you can take preventive measures.

One of the several purposes of HMI is to increase throughput and reduce manual efforts. This is possible thanks to timely, accurate, and precise machine operations. Further, people can focus on other tasks when self-operated machines complete actions.

Count on us

IRS Consultants have a wealth of experience in HMI Programming as well as interfacing to different types of PLCs. If you require our help or have any questions that you would like to ask us, reach out to us. We are happy to provide advice so you can choose the right solution for you.